The Fight Against Beer Spoilage

Fortification of malting grains with beneficial microbes may keep spoilage bacteria at bay.

This article will discuss a new way to control the levels of microbial contaminants in malted grain and increase its overall quality.

Edgar Huitema is a Scientist, Brewer & Scientific Consultant at https://extranalytics.com. Subscribe to my free newsletter to get the latest advances in science.

Malts briefly explained

As you will know, malting is the process by which we stimulate barley, wheat or oat grains to germinate. Seed germination features the release and activation of enzymes that incite the breakdown of complex sugars (that are inaccessible to yeast) and generate smaller fermentable units. While the process may appear simple and straightforward, malters have various issues to contend with in practice.

One of those issues is the presence and proliferation of (unwanted) microbes on malting grains.

As we grow our barley, wheat, and oats outdoors in soil, we expose plants to a wide range of (opportunistic) microbes. While some of these are beneficial, others are bad actors when they turn up in your brew. While microbe levels in grains tend to be low, the conditions used for seed germination (Seeds soaked in water, incubated at high humidity and 15-20 oC), also favour the growth of unwanted microbes.

Malters thus face a particular challenge - provide the optimal conditions for seed germination, while suppressing the growth of microbial contaminants.

In this post, I will highlight two related papers. The first paper focuses on identifying bacteria that can kill or reduce the levels of spoilage bacteria. The second paper investigates what happens when you mix one such bacterial isolate with grains during the malting process

As the title suggests, (Isolation and characterization of bacteriocin-producing Pediococcus acidilactici HW01 from malt and its potential to control beer spoilage lactic acid bacteria) the first paper describes the isolation of a bacterium that produces bacteriocins. Bacteriocins are small peptides, made by bacteria, that can kill other (related) microbes. Bacteriocins are agents of warfare, used by microorganisms to vie for limited resources. The authors sought to identify bacteria that can produce such peptides, hoping to help suppress the build-up of spoilage-associated bacteria.

To isolate such bacteria, Prof. Kim and his team obtained malted grain samples from various sources. They took and homogenized grains in a salt solution (Ringer's solution), which in turn, they diluted in "de Man, Rogosa and Sharpe" (MRS) broth. After incubation overnight (these are liquid cultures), the resulting suspensions were plated onto MRS agar and incubated to form small colonies.

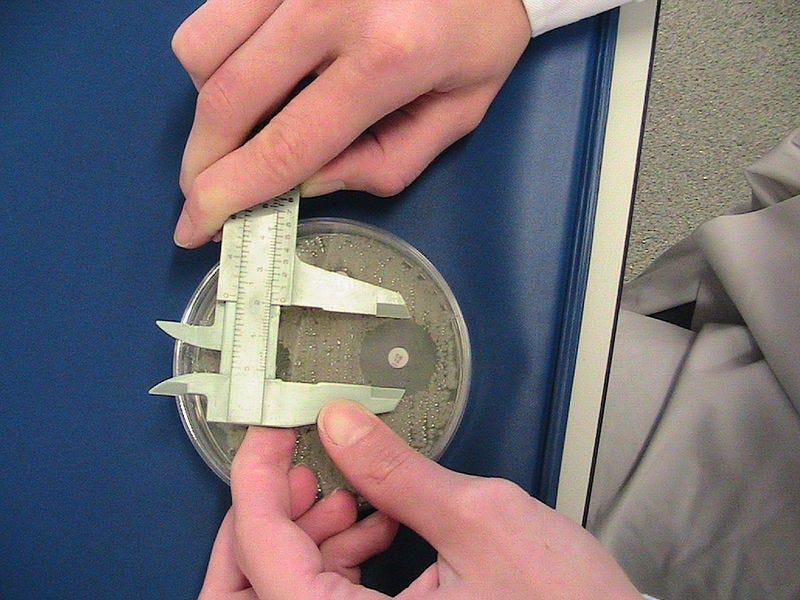

To identify bacteria that produce bacteriocins, another layer of agar, seeded with bacteria (Lb. plantarum NCDO 955 ), was placed onto the plates. This sandwich approach allows for strains (isolated from malt) to grow into colonies. The method also enables candidate strains to locally inhibit the formation of a bacterial mat. Growth inhibition (due to bacteriocins secretion) leads to round "halos" around colonies, indicating growth inhibition. These halos are a robust phenotypic character that can we can use to select candidate strains (please find a link to an informative explanation for the basis of this assay).

Using this approach (followed by 16S RNA sequencing and analyses) the authors isolated and identified a strain, Pediococcus acidilactici HW01, from malt. The first question they then asked was: how broad is the antimicrobial activity of the compounds produced by P. acidilactici?

To answer this question, the researchers used a pure culture of the bacterium to conduct growth inhibition assays. Rather than using Lb. plantarum as the "victim", they used a large and diverse set of bacterial species. These analyses revealed that growth inhibition applied to about 50% gram-positive species tested. None of the gram-negative bacteria was affected in all their assays (they used two different tests).

Having established that P. acidilactici can inhibit a fair number of bacterial species' growth, the researchers then turned their focus on the compound(s) responsible. Specifically, the researchers wished to define the conditions in which bacteriocin is active.

Heat, enzyme treatments, and testing for activity in a range of basic to acidic environments led the authors to conclude that while P. acidilactici cannot survive at high temperature, the bacteriocin is heat stable and active at low pH (above 2).

In conclusion, the authors isolated and identified a bacterial isolate (P. acidilactici) that can inhibit the growth of a range of bacterial species by producing a heat-stable and highly active bacteriocin. Notably, some of the well-known spoilage bacteria feature in the list, highlighting its potential for malting.

What is the impact of Pediococcus acidilactici HW01 on malt quality?

In the second paper by Prof Kim's group (Malt and wort bio-acidification by Pediococcus acidilactici HW01 as starter culture), the team sought to assess whether the newly isolated strain (Pediococcus acidilactici HW01) can enhance malt quality.

Members of the Kim lab generated pure P. acidilactici starter cultures and used it to fortify barley grain, before malting. As controls, they chemically acidified grains, incubated grains with (MRS) media only and used raw (untreated) barley. They then sampled during the malting process. Critically, the team measured a vast number of parameters, indicative of malting quality, afterwards. The authors determined ⍺-amylase, β-amylase and, β-glucanase activity; pH, filtration speed, and microbial contamination amongst others.

These analyses revealed the following:

As one may expect, the application of P. acidilactici HW01 lowered the pH during steeping. The production of lactic acid during steeping presumably helped to lower pH.

Increased enzymatic activity in samples, covering the entire malting process. It is well established that ⍺-amylase, β-amylase and, β-glucanase activities depend on pH. The observed increase in activity for these enzymes, therefore, may not come as a surprise. Given the direct positive impact on fermentable sugar content, this is excellent news (for some info on brew enzymes, have a look at this useful resource)

It increased filtration speeds. Filtration speed is a character that informs malt quality. The observed increase, probably due to reduced levels of complex sugars (starch and β-glucans) is, again, good news.

Microbial stability is probably one of the most interesting characters, considering the narrative and reasons for starting this work. Plating and characterizing the microbial population throughout malting revealed that some of the spoilage-associated bacteria (such as Pseudomonas spp.) had come down compared to controls. These results are consistent with their previous findings and likely due to bacteriocin activity.

In conclusion, by fortifying grains with beneficial bacteria such as P. acidilactici HW01, malt producers can simultaneously make malts more acidic, increase malt quality and control the levels of spoilage-associated bacteria.

This is yet again, a great example of how microbial ecology and diversity can be used to help solve important problems in brewing beer.

Cheers 🍻🍻

Edgar, The Beerologist.