Micro-Mashing: A New Technology that Will Accelerate Beer Recipe Design

Micro-scale mashing to dissect beer biochemistry aided by statistical power

Brewing beer is an exercise in experimentation. You (brewers) tinker with recipes more often than not, try new ingredients and combinations to create the best wort. Mashing is an integral part of the design process.

In a nutshell, mashing describes the process in which grains (of a pre-defined composition) are steeped in water and incubated at specific temperatures to extract and enzymatically convert starch to simple sugars. Along with starch, grains also release proteins, which break down to form small peptides under the right conditions. As you will appreciate, many factors (grain bill, temperature, incubation times, etc.) help determine your wort's final composition.

It will not surprise you that factors can interact and influence each other. In other words, we know a little about the biochemistry of mashing, but comparatively little about the factors that drive the process. For anyone to understand the complex web of interactions, leading to a particular characteristic, a robust experimental platform is needed. What do I mean by a robust platform?

Repeatable, reproducible and representative.

One of the significant problems in brewing and beer design is the scale. Most brewers would refrain from optimizing their mash conditions at a large scale. But using even a 23L mash volume comes with significant expenses and time commitment. Therefore, the question is to what extent you can reduce mashing volume but still represent (commercial) production process parameters.

In this context, I stumbled upon a recently published paper aiming to achieve just that milestone—developing a robust platform, allowing research into mashing conditions that represent large scale mashing.

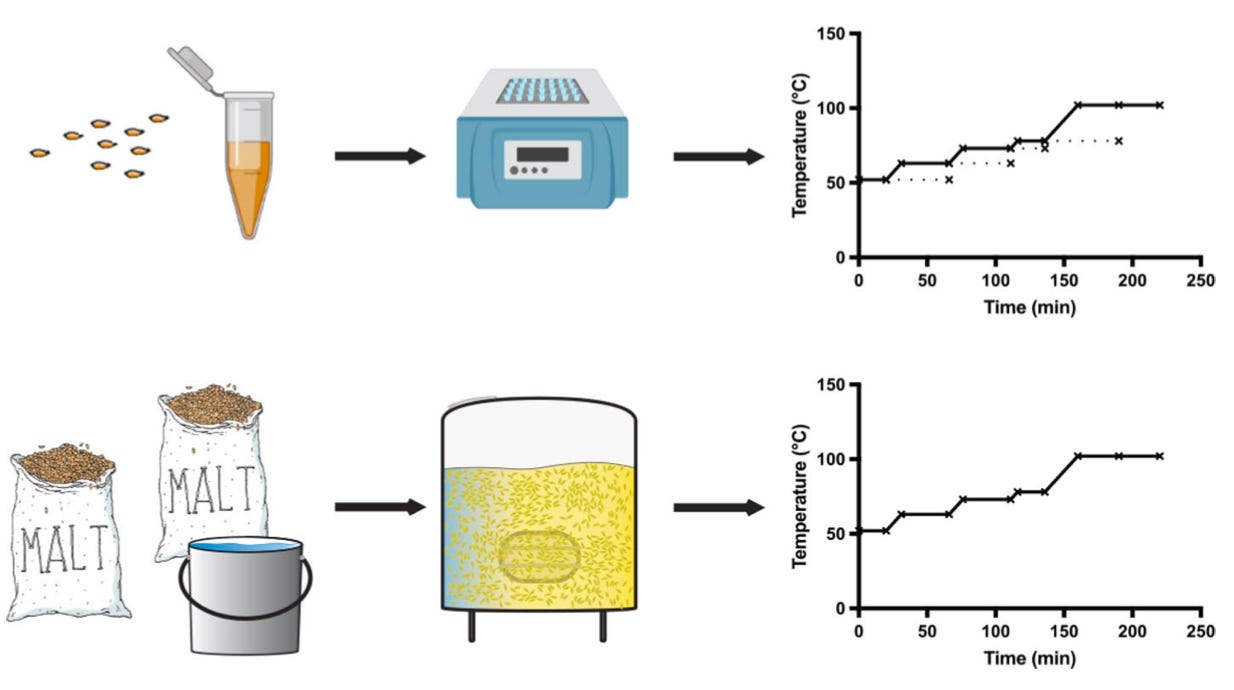

In their published work, the group of Prof Benjamin Schultz not only devised a benchtop micro-mashing system, but they also demonstrate that the wort produced at micro-scale (1 mL) is mostly the same as wort produced in 23L (23,000 mL) batches.

Below, we will look at what they did.

As you can see above, the process was relatively standard as far as the full-scale 23L volume was concerned. Pale ale malt was mixed in 23 L of water and mashed with a multi-step programme. The authors performed their micro-scale mash in a 1 mL volume, using a nearly identical schedule. Samples were taken throughout.

There are two crucial questions that one needs to answer.

How representative (similar) is the micro-mash wort when compared to wort from a 23 L mash?

How consistent is the (micro-) mash process, can it be used to tease out the parameters that influence wort characters?

The answer to both questions is: pretty good.

To come to these answers, the authors first looked at wort protein abundance in their samples. Using (LC-MS/MS mass spectrometry, the authors measured the abundance of 78 different proteins, across all mash and boiling stages in both volumes. These analyses revealed that the release and accumulation of these proteins followed the same pattern (an increase over time), with the same dynamics and absolute levels.

Yeast requires a free amino nitrogen (FAN) source to synthesize its own proteins and facilitate growth. Proteolytic cleavage of proteins during the mash is an important process that increases FAN and subsequent brewing steps such as fermentation. Therefore, the authors measured the abundance of well-known small peptides in samples from both 23 L and 1mL setups.

Again, the authors found a great similarity between samples, indicating that both protein and peptide levels are not affected by mashing scale. This begs the question, are there any differences that arise because of the mashing scale? The answer is yes, but the authors were not sure what the difference exactly is!

Sugar content measurements and specific gravity readings found that while sugar content profiles were quite similar (as determined by Multiple Reaction Monitoring (MRM) LC–MS/MS, specific gravity was significantly different between samples. These results indicate that while the major and most important constituents and processes in mashing can be reproduced in a 1 mL volume, other extracted compounds (the authors suspect higher starch extraction efficiency in the micro-mash), may cause higher specific gravity values in the micro-mash samples.

Finally, the authors asked whether you can use the micro-mash platform to investigate mashing parameters. For this, they carried out a series of experiments in which they tried to determine whether peptide abundance is affected more by incubation time or temperature.

To cut a long story short, they found that specific peptide families changed in abundance by changing temperature, whereas others responded to incubation time changes. These results illustrate the complexity of wort production and illustrate this new experimental platform's power and potential.

Micro-mashing will become super important for various reasons. Firstly, brewers can finally get help to get to grips with the complex interactions that take place between ingredients and processes. Secondly, micro-mashing may become an important tool to evaluate the quality of ingredients and/or suitability of grain cultivars.

There is little question that this technology will become a staple in the growing toolbox, available to QC services and setups.

Until next time.

Cheers,

Edgar, The Beerologist.

Edgar Huitema is a Scientist, Brewer & Scientific Consultant at https://extranalytics.com. Subscribe to my free newsletter to get the latest advances in science. Contact The Beerologist at ExtrAnalytics if you wish to discuss your needs and our research.